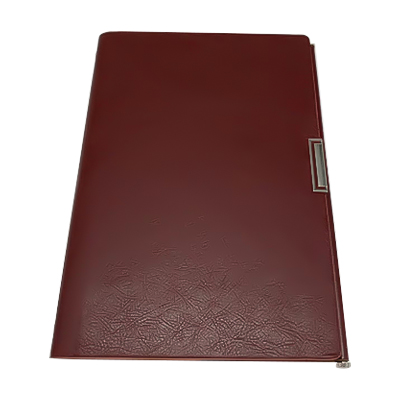

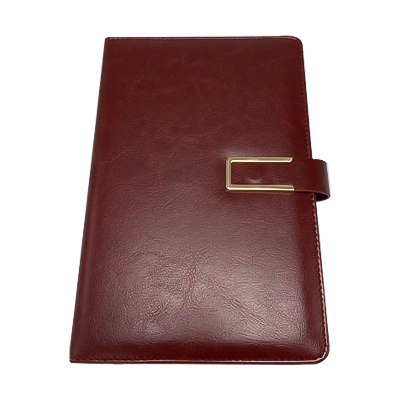

Coated Duplex Board Paper has many advantages in the packaging industry. With its excellent surface coating, this paperboard not only gives the packaging a smoother and more uniform appearance, but also improves the quality performance of the product on many levels. The smooth surface of coated duplex board is crucial to the improvement of printing effect. The coating can provide a smooth and uniform printing surface, ensuring that each board has the same gloss and texture. This surface not only makes the pattern, text and color clearer and brighter, but also presents fine details, greatly enhancing the visual appeal of the packaging. Through this high-quality printing effect, the brand image is effectively conveyed, and the packaging appears more professional and high-end, whether it is the presentation of color or the depiction of details, it can achieve the ideal effect. Coated duplex board is often used for the packaging of high-end goods, such as luxury goods, cosmetics, electronic products, etc. These products have high requirements for the appearance of the packaging, and coated board is the ideal choice to meet this demand.

Coated duplex board can effectively improve the grade of the packaging. Due to the gloss of the coating and the delicate surface treatment, this board looks smoother and more textured, giving the entire packaging a high-end appearance. This high-end packaging design not only enhances the market competitiveness of the product, but also establishes a high-value image of the product in the minds of consumers. Consumers often judge the value of the product and the reputation of the brand through the packaging. Exquisite and high-end packaging can increase the attractiveness of the product and promote sales.

In addition to the advantages of appearance, coated double-sided paperboard also plays an important role in improving product quality. The coating itself can increase the durability of the paperboard, making it more resistant to abrasion, water and moisture, which is especially important during the packaging process. During transportation, paperboard often encounters moisture, scratches and compression, and coated double-sided paperboard can effectively resist these external factors, ensuring that the packaging is not easily damaged, thereby protecting the safety of the contents. This durability allows the product to remain in good condition during long-distance transportation or stacking, improving the reliability of the packaging and the overall quality of the product.

The structure of coated double-sided paperboard is usually stronger, and its coating can enhance the paperboard's resistance to compression and bending. This strength and stability is critical for goods that need extra protection, especially those fragile or valuable items that are easily damaged. By improving the strength of the cardboard, coated double-sided cardboard can effectively prevent the product from being damaged by external forces during the packaging process, thereby improving the protective performance of the packaging and making the final product more high-quality.

Coated double-sided cardboard also has good processability and can support various complex post-processing technologies. Due to the characteristics of the coating, the cardboard can maintain good stability during cutting, folding, die-cutting and other processes, reducing problems during processing. This allows the packaging to be more accurately produced in the shape and effect that meets the design requirements, improving the overall appearance of the packaging. In the packaging design of high-end products, precise processing and exquisite appearance are crucial. Coated double-sided cardboard provides this processing convenience and meets the needs of high-quality packaging.

Coated double-sided cardboard also has certain advantages in environmental protection. It usually uses environmentally friendly coatings and meets the standards of recyclability and degradability, which makes it a material that more and more brands prioritize in packaging design. With the improvement of environmental awareness, consumers are paying more attention to sustainable development. Packaging using environmentally friendly materials can enhance the brand's sense of social responsibility and attract consumers who pay attention to environmental protection. This environmental friendliness not only helps to enhance the brand image, but also wins more favor for products in a highly competitive market.

The versatility of coated double-sided paperboard makes it suitable for a variety of complex packaging designs. In addition to conventional printing, coated double-sided paperboard can also support post-processing technologies such as hot stamping, partial UV coating, and die-cutting. These processing technologies can further enrich the expressiveness of the packaging, so that the packaging not only has good visual effects, but also can bring consumers a higher experience in touch. Through these fine post-processing, the details and design level of the packaging are improved, further enhancing the market appeal and competitiveness of the product.

English

English Deutsch

Deutsch Français

Français Español

Español русский

русский عربى

عربى