Introduction

In the packaging industry, paper-based materials play a critical role in balancing cost, durability, and sustainability. Among these materials, White Duplex Board Paper stands out as one of the most widely used options. For beginners new to packaging design or sourcing, understanding this material is essential. White Duplex Board Paper is commonly applied in food boxes, pharmaceutical cartons, stationery covers, and cosmetic packaging. Its versatility comes from its unique structure, printability, and cost-effectiveness.

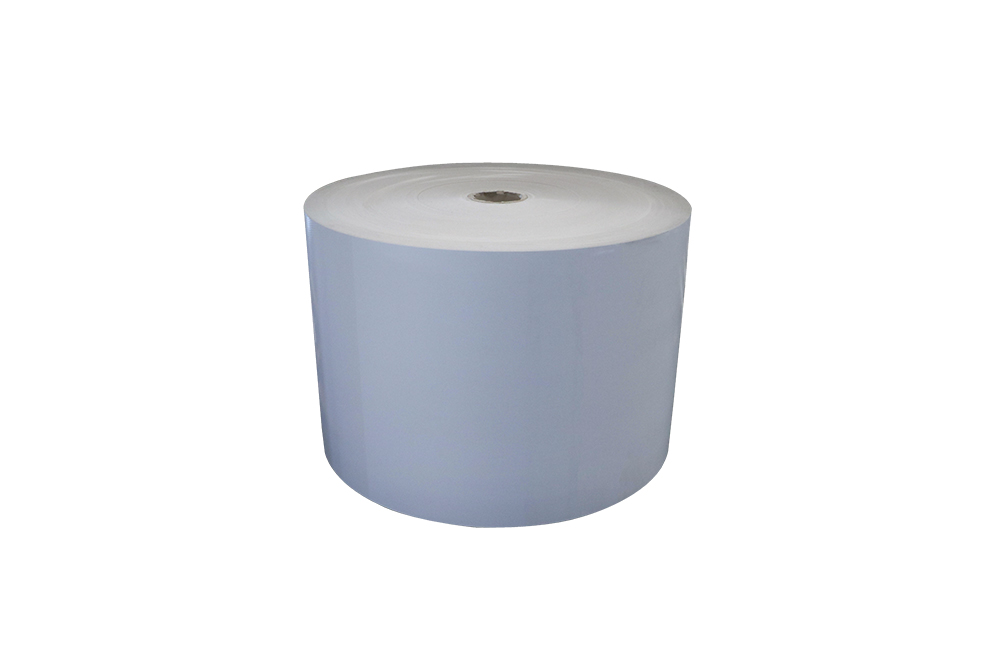

What Is White Duplex Board Paper?

Definition and Structure

White Duplex Board Paper is a type of paperboard created by combining two layers of paper pulp. This layered structure provides greater thickness and rigidity compared to ordinary paper.

Key Characteristics

- Duplex structure: Two layers bonded together for extra strength.

- White coating: The surface is often coated for brightness and smoothness.

- Back color: Depending on the grade, the reverse side may be grey or white.

Why It Matters for Packaging Beginners

For those entering the packaging industry, White Duplex Board Paper is often the first choice because it is cost-effective, printable, and eco-friendly. It fills the gap between low-strength kraft paper and more expensive solid bleached boards.

Key Features of White Duplex Board Paper

Strength and Durability

White Duplex Board Paper is much stiffer than regular paper, making it suitable for holding medium-weight products. Its rigidity ensures cartons do not collapse easily, even when stacked.

Printability

The smooth, white surface enables high-quality printing. Logos, images, and branding appear sharp and vibrant, which is especially important for retail packaging where appearance influences consumer choice.

Thickness Variety

The board is available in different GSM (grams per square meter), usually ranging from 230 GSM to 500 GSM. A higher GSM indicates more thickness and strength, giving businesses flexibility for different packaging needs.

Grades of White Duplex Board Paper

Coated One Side (C1S)

- Definition: One side is coated with a white printable surface, while the other side is grey.

- Best for: Inner packaging or cartons where only one side requires printing.

- Example: Medicine boxes or electronics packaging.

Coated Both Sides (C2S)

- Definition: Both sides are coated and appear white.

- Best for: Premium packaging that requires double-sided printing.

- Example: Food packaging, cosmetics, and gift cartons.

| Grade Type | Coating Description | Typical Uses |

|---|---|---|

| C1S | One side white coated, back side grey | Medicine cartons, electronics |

| C2S | Both sides white coated | Food boxes, cosmetics, luxury packaging |

Common Applications

Food Packaging

White Duplex Board Paper is widely used in pizza boxes, bakery cartons, frozen food packaging, and fast-food containers. Its grease resistance and excellent printability make it ideal for the food sector.

Consumer Goods Packaging

Products such as mobile accessories, toys, and small electronics are commonly packaged in duplex board cartons. The stiffness ensures product safety during storage and transport.

Pharmaceuticals and Cosmetics

Pharmaceutical cartons often use duplex board for lightweight yet protective packaging. Similarly, cosmetic companies prefer C2S boards to achieve high-quality printing that enhances the premium image of their products.

Stationery and Printing

In the stationery industry, duplex boards are used for folders, business cards, and book covers due to their firm structure and excellent ink absorption.

Advantages of White Duplex Board Paper

Cost-Effectiveness

Compared to premium packaging materials like solid bleached sulfate (SBS) or plastic, duplex board is far more affordable, making it suitable for large-scale production.

Eco-Friendliness

Recyclability is a significant advantage. As a biodegradable material, it aligns with the increasing global demand for sustainable packaging.

Customization Options

Duplex board can be cut, folded, laminated, embossed, or varnished, allowing creative packaging designs.

Enhanced Print Quality

The coated white surface provides excellent ink absorption, ensuring sharp, colorful branding.

How to Choose the Right Duplex Board

Consider GSM and Thickness

- 230–300 GSM: Lightweight packaging, such as small cartons.

- 300–400 GSM: Medium-duty packaging, such as food boxes.

- 400–500 GSM: Heavy-duty packaging, including electronics and hardware.

Check Print Requirements

If your packaging requires full-color graphics or branding on both sides, C2S is recommended. For basic printing needs, C1S may be sufficient.

Balance Budget vs. Usage

Businesses must balance cost vs. appearance. C1S is ideal for cost-sensitive projects, while C2S is preferred for premium products.

Handling and Storage Tips

Protect from Moisture

Like all paper materials, White Duplex Board Paper is vulnerable to humidity. Moisture may cause warping or weakening. Always store in a dry environment.

Stack Properly

Boards should be stacked flat and evenly to avoid bending. Heavy loads should not be placed on top.

Use Protective Wrapping

During transport or long-term storage, covering with plastic wrap helps prevent dust and damage.

Maintain Temperature Control

Extreme heat or cold may affect the coating. Storing in a controlled indoor space ensures quality preservation.

English

English Deutsch

Deutsch Français

Français Español

Español русский

русский عربى

عربى